strong use cases:

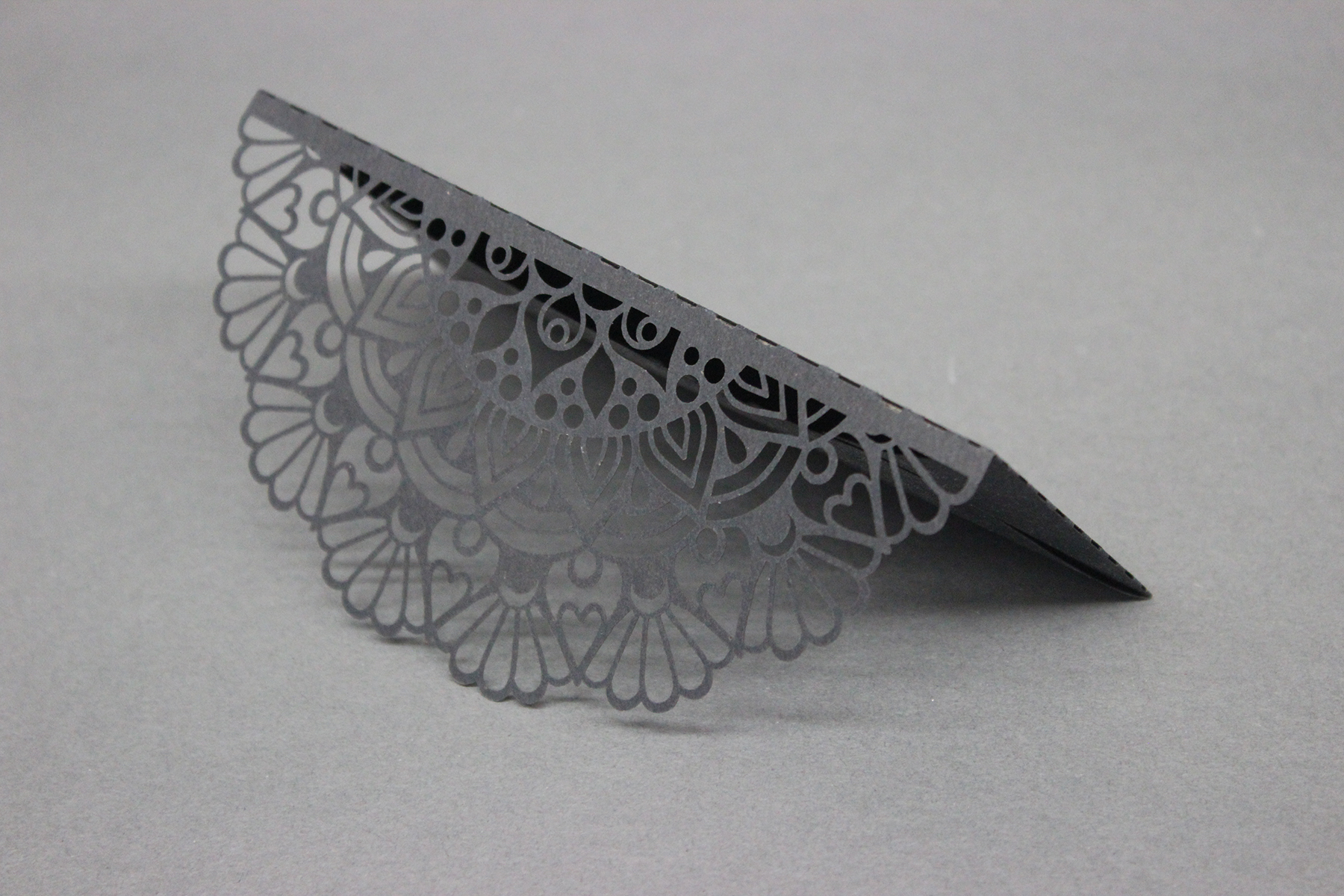

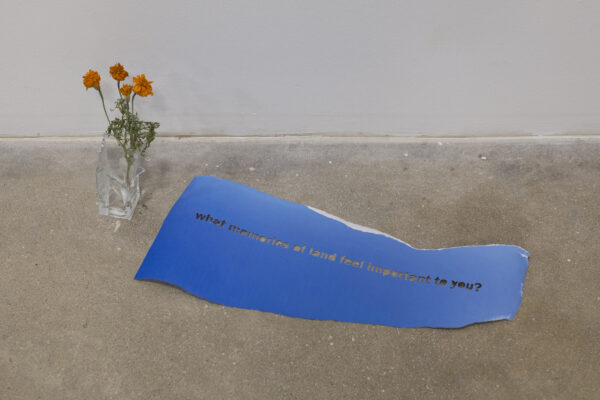

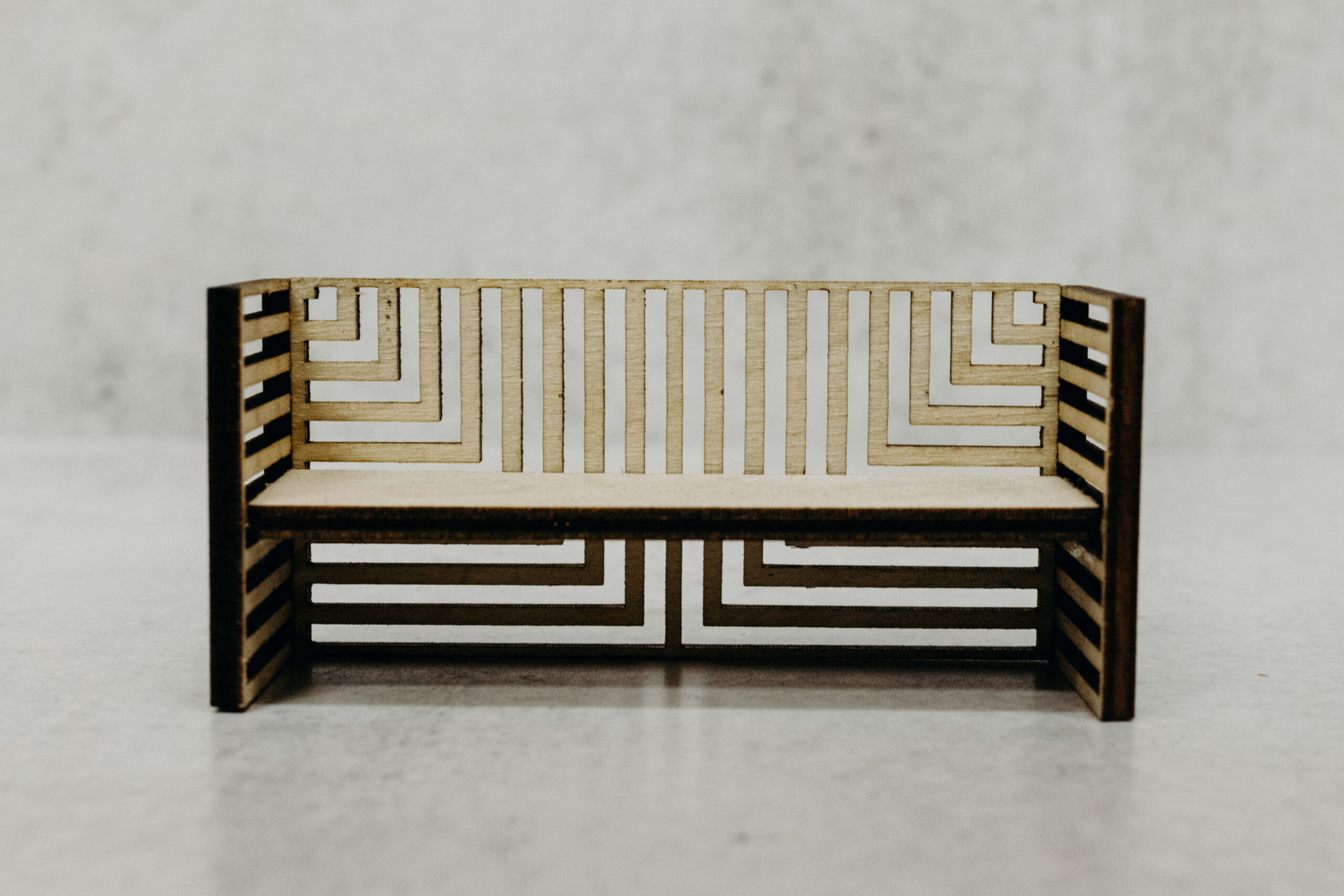

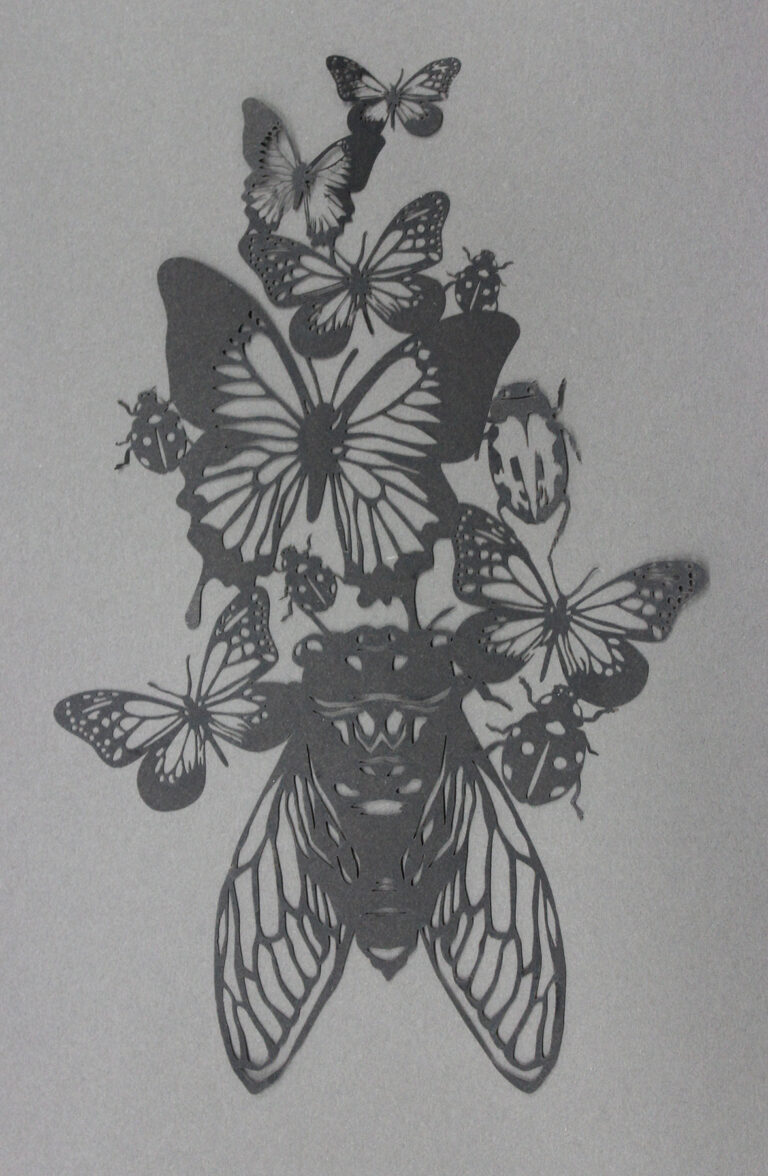

- cutting intricate paths and/or precise patterns

- fabricating designs that require a zero clearance tool width

- fabricating matching components

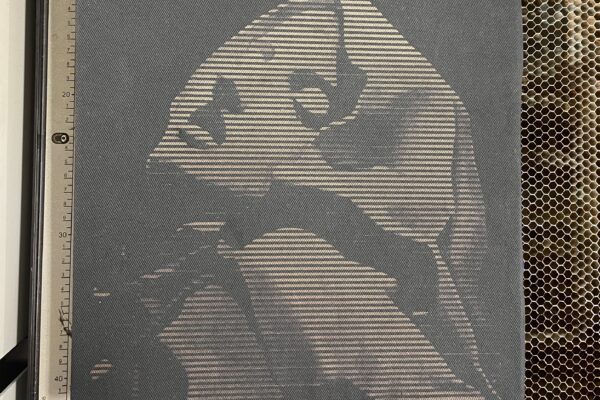

- engraving wood or rubber to make stamps

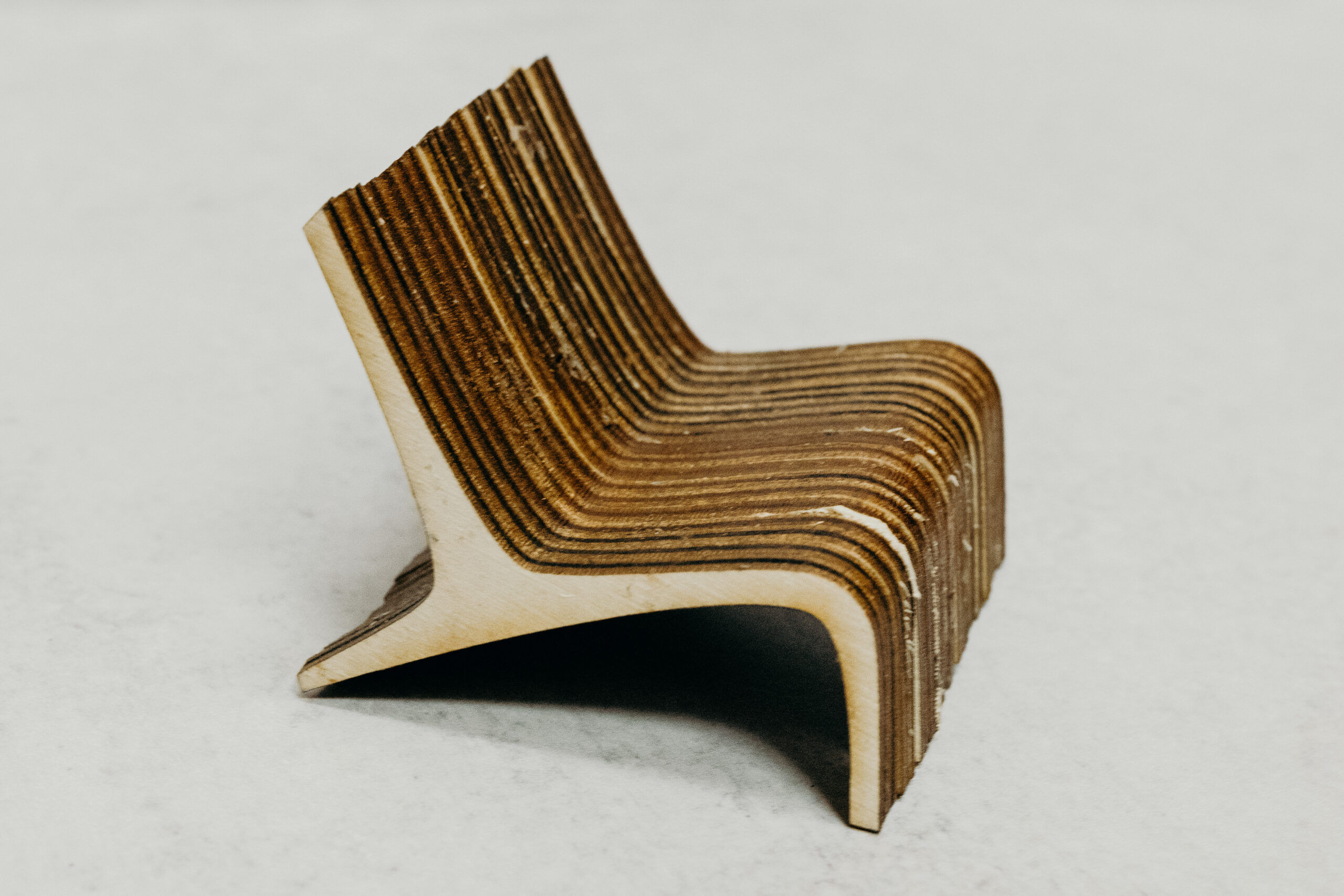

- creating sculpture using stacked boards

not useful if:

- material thickness to be cut is greater than 1/4″ (or 1/2″ if you are willing to make two passes)

- material to be machined is not 100% organic

Epilog Zing Laser

- 40 Watt Laser

- Bed Size: 16″ x 12″

- Material Thickness up to 1/4″ cut in 1 pass; 1/4″ – 1/2″ cut in 2 passes

- download the Epilog Zing Manual

Epilog Helix Laser

- 50 Watt Laser

- Bed Size: 24″ x 18″

- Material Thickness up to 1/4″ cut in 1 pass; 1/4″-1/2″ cut in 2 passes

- download the Epilog Helix Manual

CAN BE CUT & ENGRAVED WITH NODELAB LASERS

- paper

- matboard

- chipboard

- corrugated cardboard sourced from the UW Markerspace

- provided plywood

- hardwood and softwood

- natural felt it’ll smell like burnt hair for a long time!

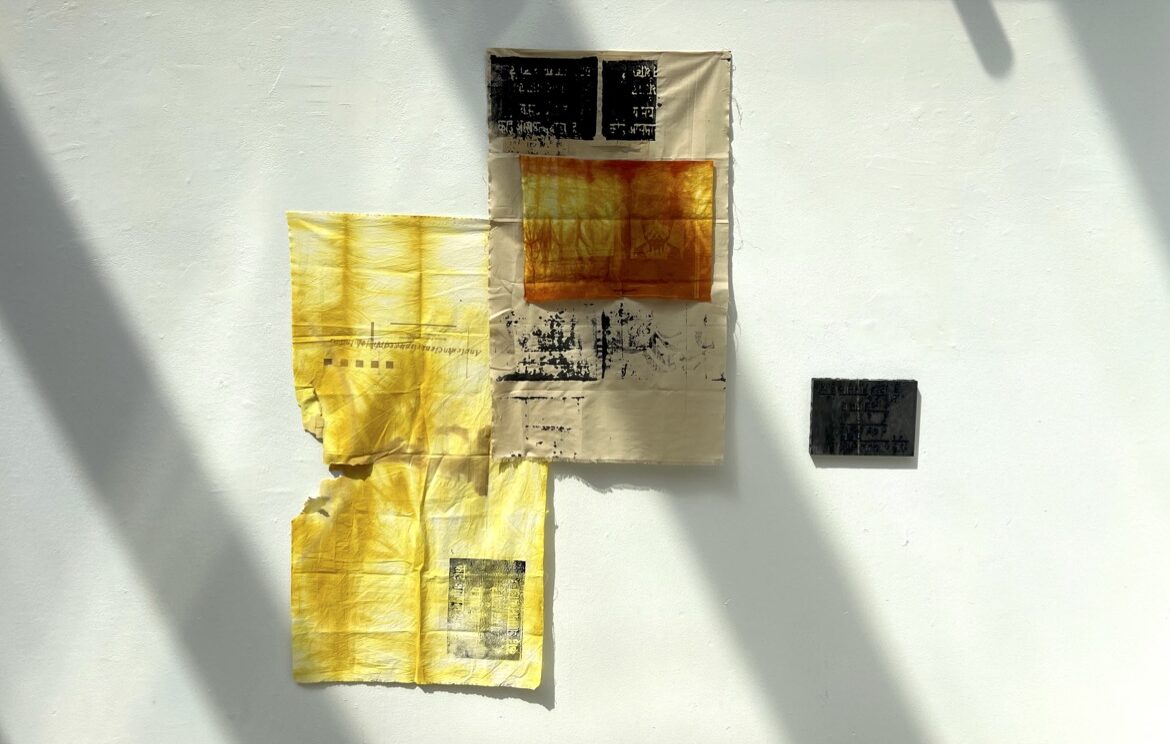

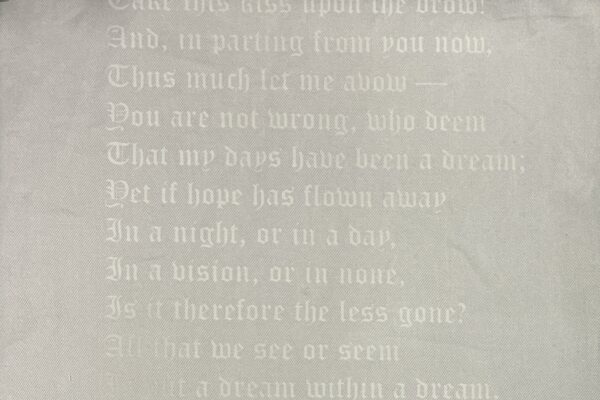

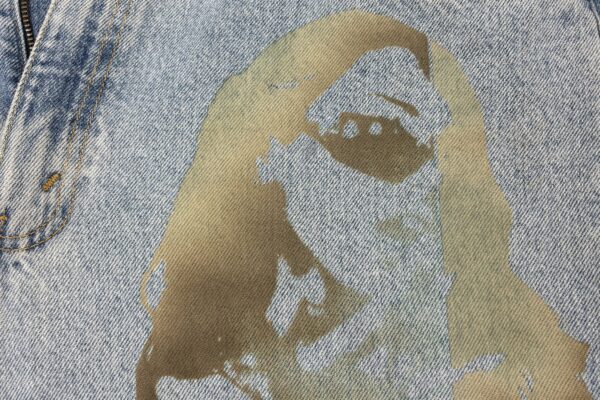

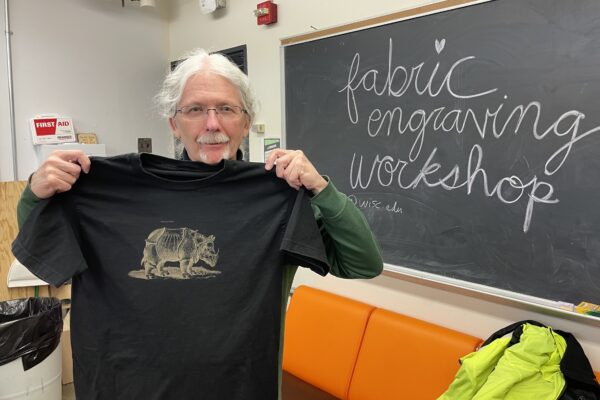

- 100% wool fabric

- 100% cotton fabric

- Any 100% natural textile / fabric

- Leather (increase frequency to compensate for leather density)

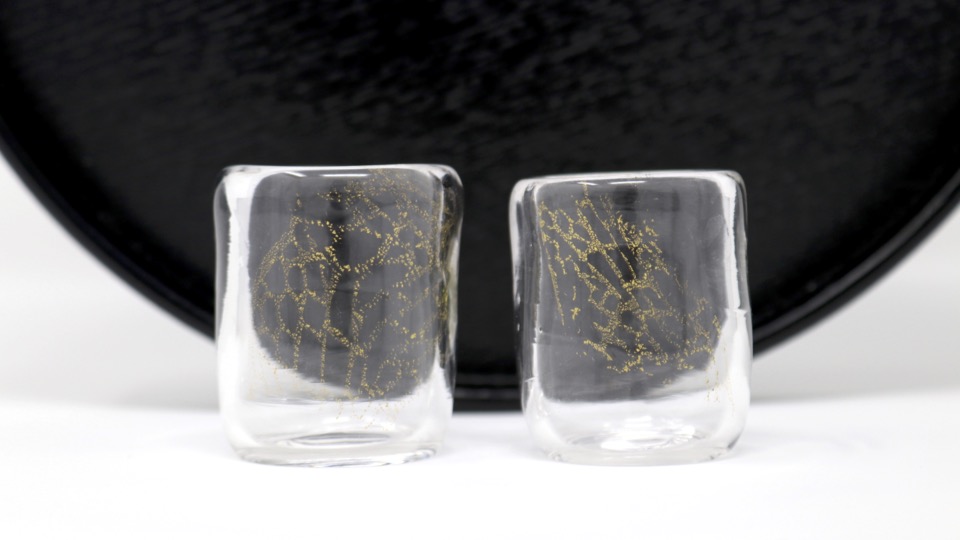

- Glass etching only

DO NOT USE WITH NODELAB LASERS

- corrugated cardboard NOT sourced from the UW Markerspace

- random store-bought plywood

- any material coated or sealed with plastic, acrylic, poly, urethane, oil

- synthetic felt

- all synthetic textiles / fabrics

- plexi or acrylic sheets

- vinyl, pleather, PVC, most metals, painted and inked surfaces

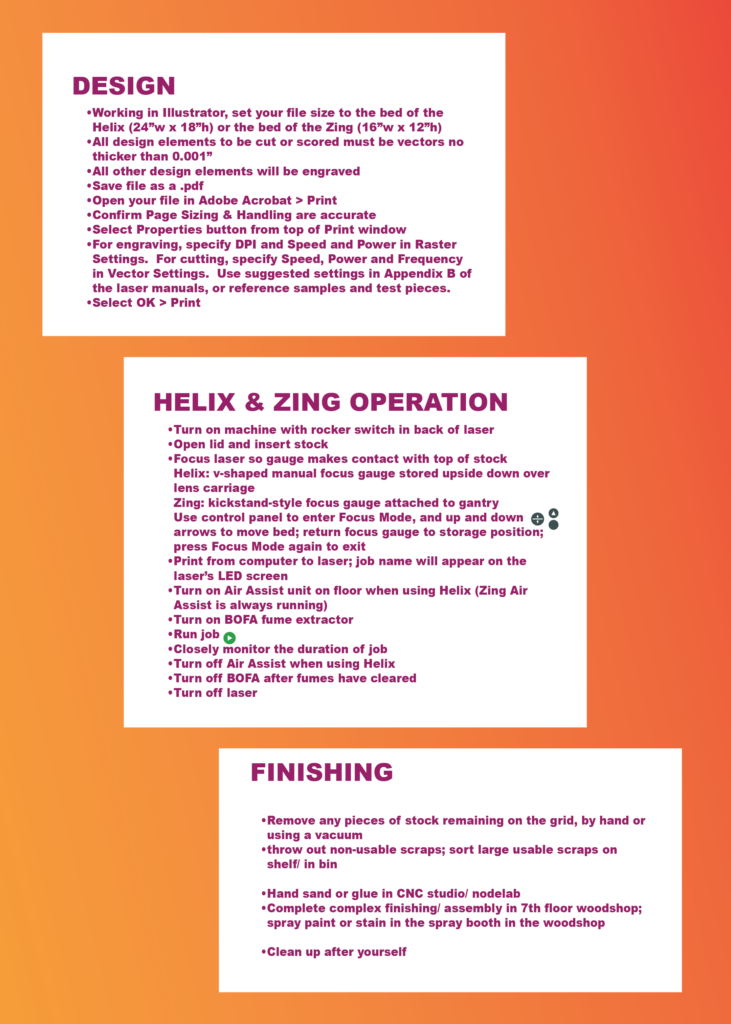

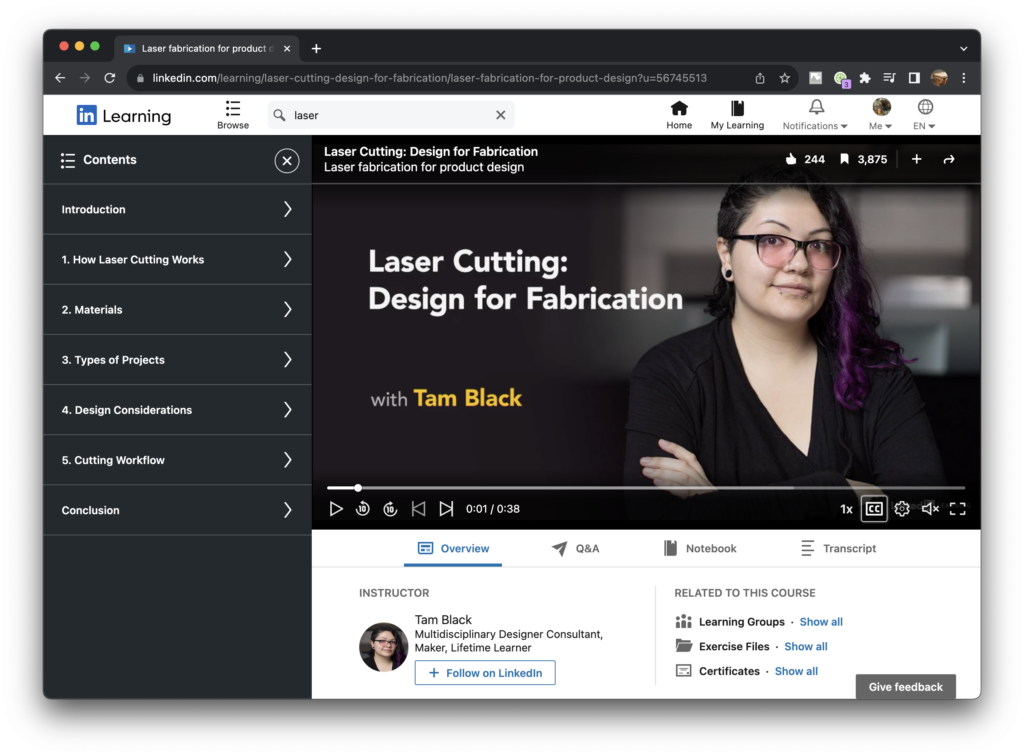

Laser Cutting: Design for Fabrication

screen this video tutorial by signing into your UW Linkedin Learning account