strong use cases:

- range of colors (without post-processing) is required

- scale/ build volume needs to be as large as possible

- dissolvable support will keep a delicate print from being damaged in post-processing

- exact multiples of a complex model required

- time commitment of resin printing including post-processing is prohibitive

- expense of resin is too prohibitive

- model will be burned out in a foundry casting purposes in metal or glass

- prototyping, creating a component to connect different media, printing a master design to create a mold from (also use cases critical to resin printing)

not useful if:

- printing extremely fine detail

- transparency of print is key to design

- sheer strength of print is critical

- significant variables in setting up g-code is prohibitive

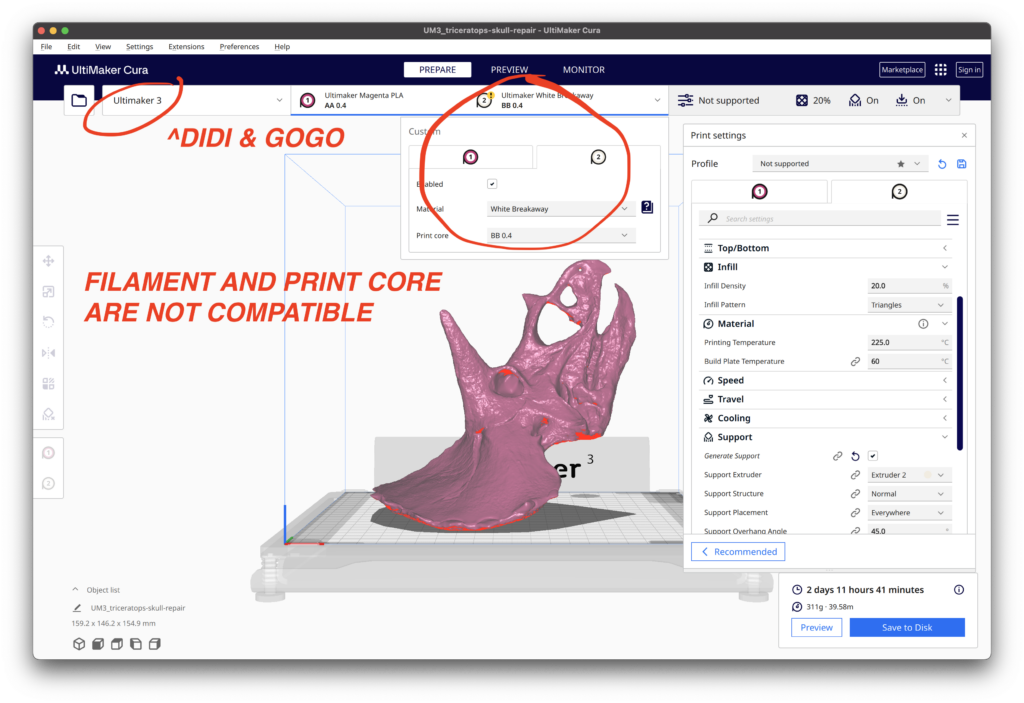

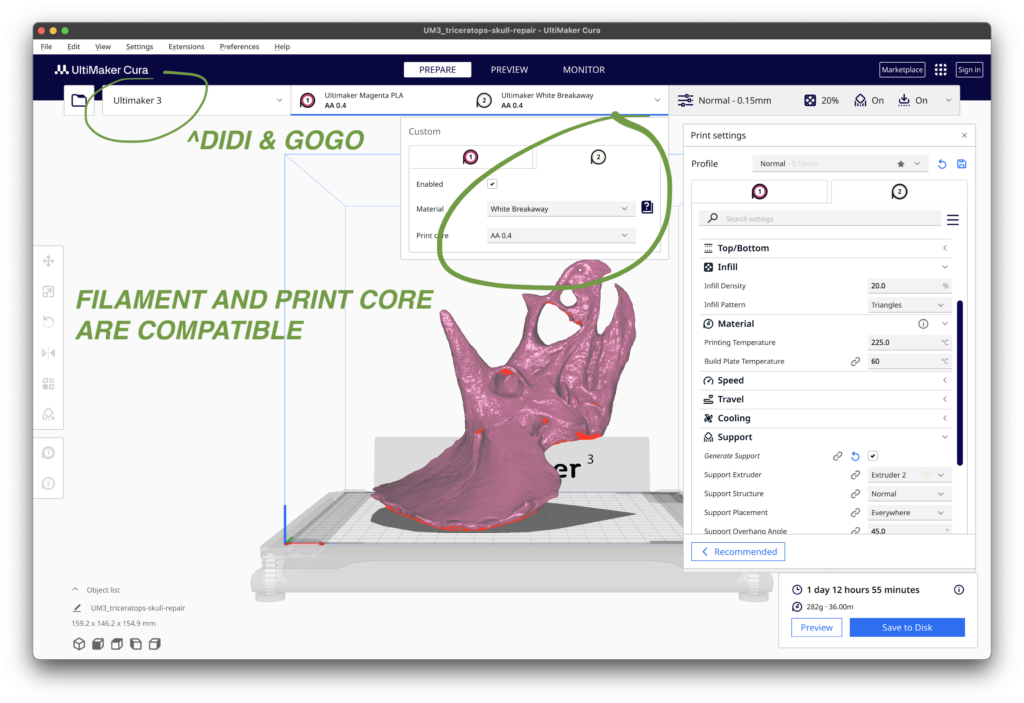

Ultimaker 3

- loaded with PLA breakaway support filament

- build volume, single extrusion:

21.5 w x 21.5 d x 20 h cm

8.5″w x 7.5″d x 7.9″h - build volume, dual extrusion:

19.7 w x 21.5 d x 20 h cm

7.8″w x 8.5″d x 7.9″h

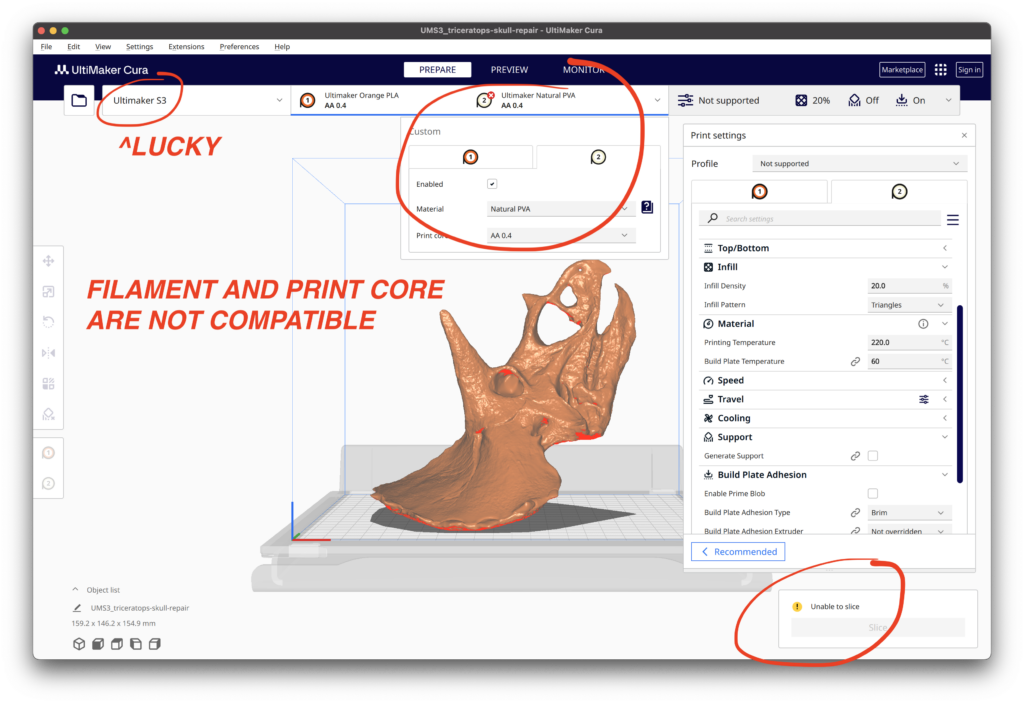

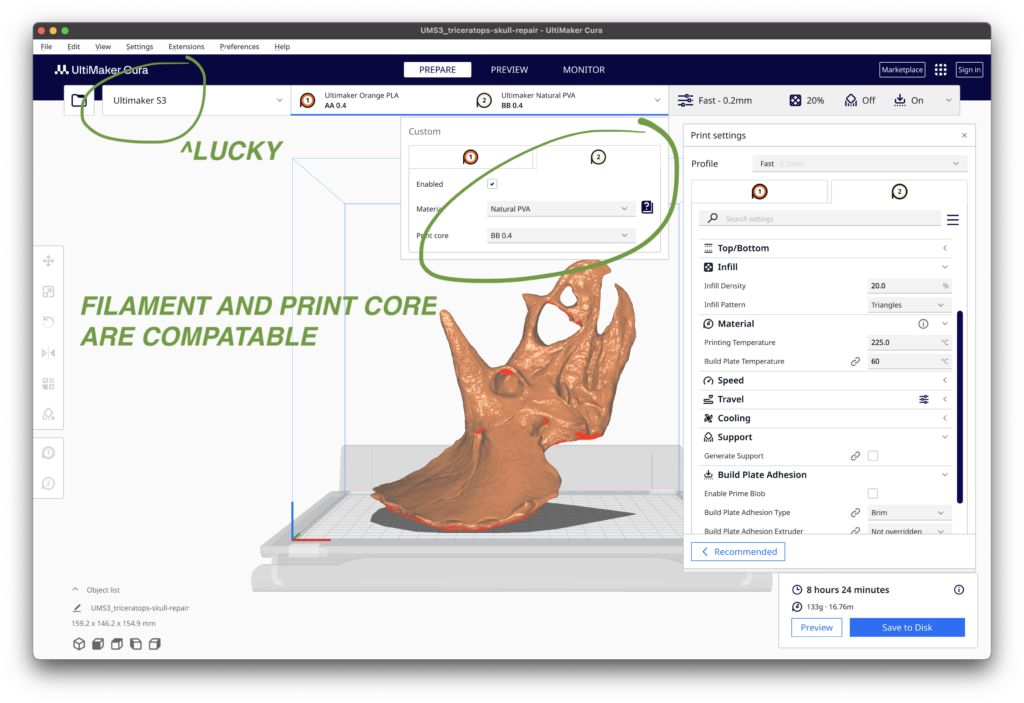

Ultimaker 3S

- loaded with PVA dissolvable support filament

- build volume:

23 w x 19 d x 20 h cm

9.1″ w x 7.4″ d x 7.9″ h

Prusa MK IV

- FDM 3D printer

- loaded with PLA 1.75mm

- build volume, single extrusion: 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in